Let's go ...

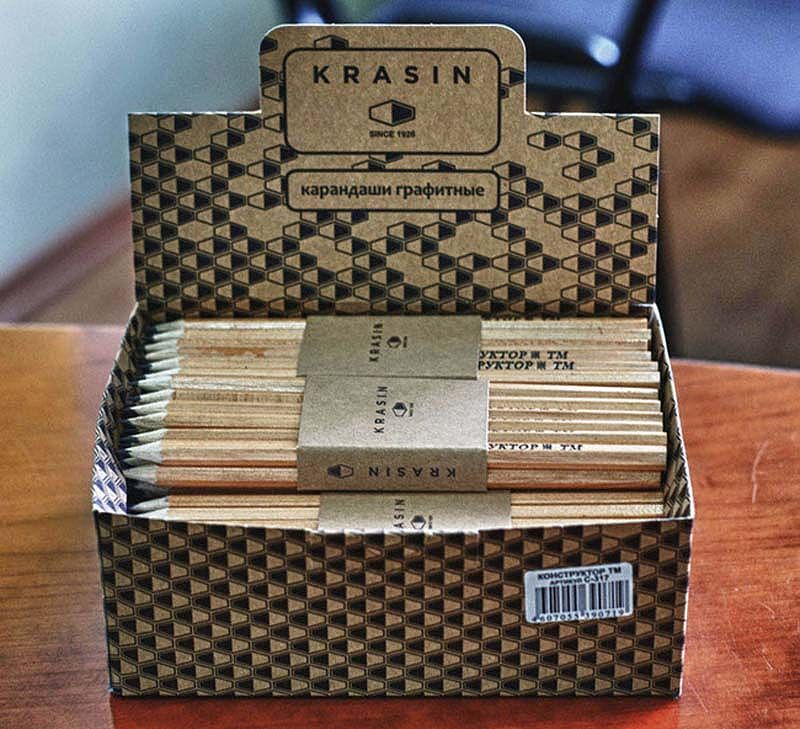

To see with their own eyes the process of the production of pencils, we go to the Moscow factory Krasin. This is the oldest pencil production in Russia. The factory was founded in 1926 with the support of the government.

The main task of the government was to eliminate illiteracy in the country, and it was necessary to make the stationery available. After the collapse of the Soviet Union, the Krasin factory remains the only manufacturer of pencils in the CIS with a complete production cycle. This means that the factory produced everything - from pencil to the end product - pencils. Let's take a closer look at the process of production of pencils.

For the production of pencils in a factory receives a specially crafted and arranged plate of limes. But before they will be involved, it is necessary to make writing rods.

2. Let us turn to the workshop production of pencil rod. Writing rods are made from a mixture of clay and graphite. Preparation of the necessary mixture begins with just such processing plants, where shredded clay. Shredded clay pipe the goes for the next leg of production.

3. In the next section are special mill, where clay is more finely ground and mixed with water.

4. Plants for the preparation of a mixture of clay and graphite. Here the mixture for future rods get rid of impurities and preparing for further processing.

5. It should be noted that the production of slate used only natural ingredients, which makes the production of environmentally-friendly. Setting the compression mixture. Obtained from semi-prepared rods. Waste from the production actually not, because they use them again.

6. On this part of production are already rods themselves, but that they were in pencil, they will have held a number of manufacturing operations.

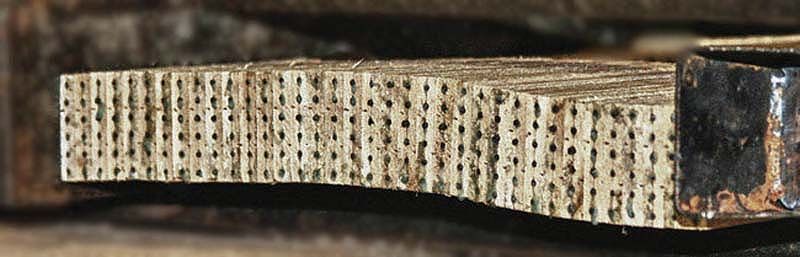

7. The technology of obtaining cores - like extrusion. Carefully prepared and stirred mass is extruded through a special stamp with holes.

8. After this piece of writing for the rods are placed in a special container.

9. And dried in the oven for 16 hours.

10. After that, the rods carefully sorted by hand.

11. Here is the job of sorting the rods. This is a very difficult and tedious work. For a table lamp sleeping cat.

12. After sorting the rods roasted in a special oven. Annealing temperature of 800 to 1200 degrees Celsius and has a direct impact on the final properties of the rod. Depends on the temperature of the pencil hardness, which has 17 shades - from 7N to 8V.

13. After annealing, the rods under particular pressure and temperature are filled with fat. This is necessary to give them the necessary writing properties, intensity features, ease of sliding quality sharpening, easy erase eraser. Depending on the desired hardness of the rod can be used: salomas, confectionery fat or beeswax and carnauba wax. Outputs section of core production.

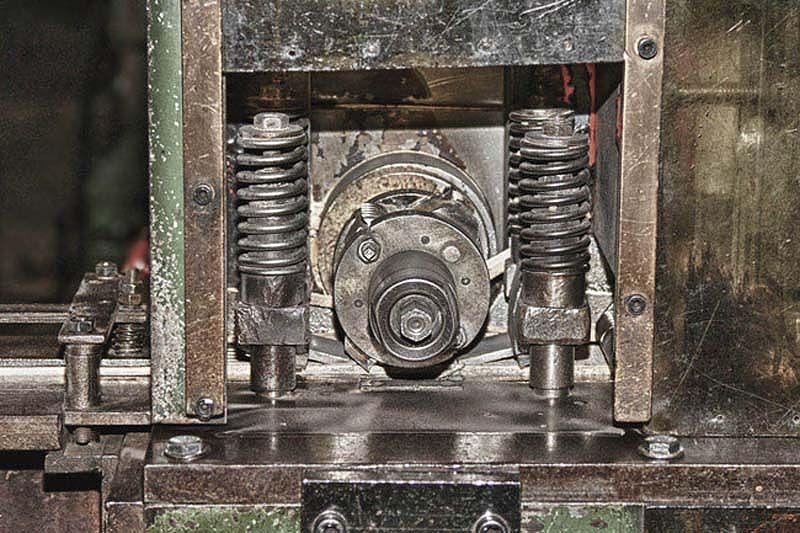

14. After the fall of the rods to the assembly. Here on these machines are prepared tablets for pencils. They are cut grooves for installation writing rods.

15. The cutting part of the machine grinds the groove at the plate.

16. Plates are automatically assigned to a clip here.

17. Then on another machine rods are placed in a pre-prepared plates.

18. After laying the halves are glued together with white glue boards, and they are left to dry under pressure. The essence of this operation is that the bar is not very attached to a plate. Its diameter is larger than the diameter of the groove, and in order to design withdrew - requires a press. The rod will be held in the same wood not by glue and by tightness wooden shell (specially designed in such a way in the construction of prestressing pencil).

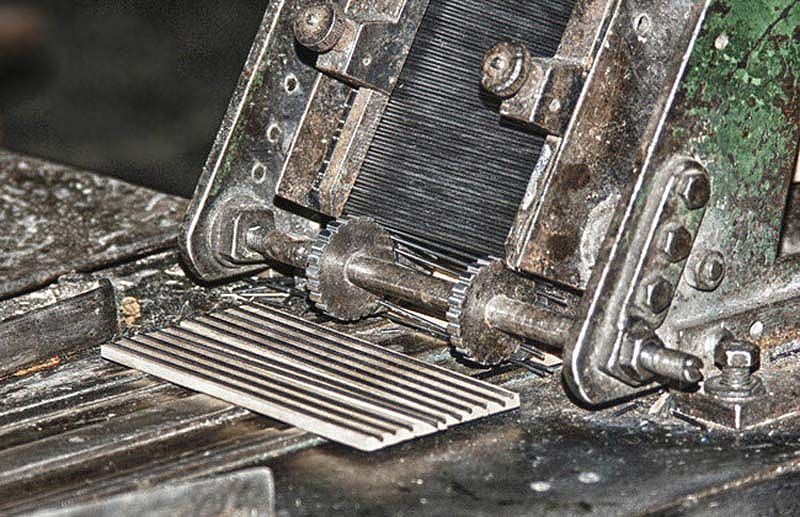

19. After drying, the workpiece being cut with special cutters to individual pens.

20. Pencils are cut gradually over several cycles.

21. The output is a ready-made, but not colored pencils.

22. Already at this stage the shape of a pencil through the type of profile cutting cutter.

23. Next on special lines is Priming the surface pencil. When painting pencils applied enamel, manufactured at the plant. These are made of enamel safe for human components.

24. Line for painting pencils.

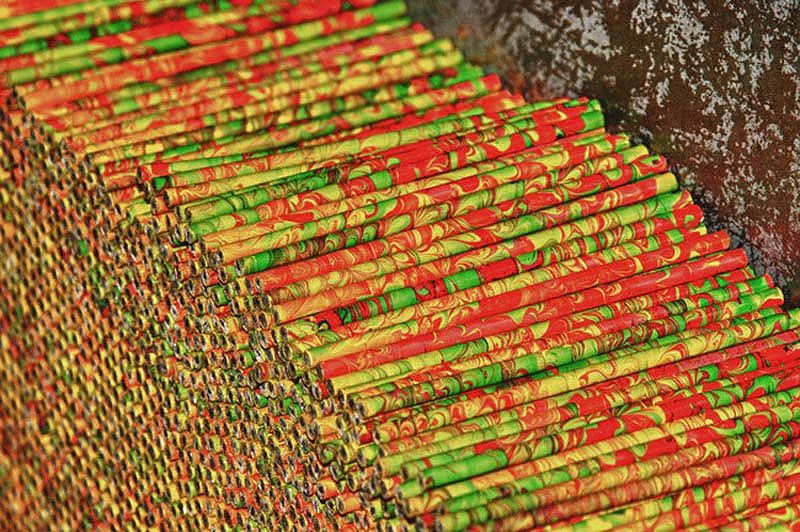

25. I think that the stores we have seen many times gift pencils, colored colorful patches. It appears to them as paint, apply a whole specially developed technology. Here is a small piece of the process of painting.

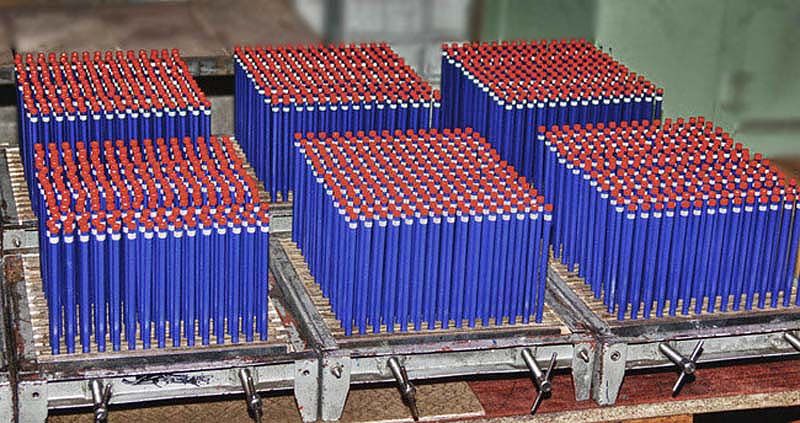

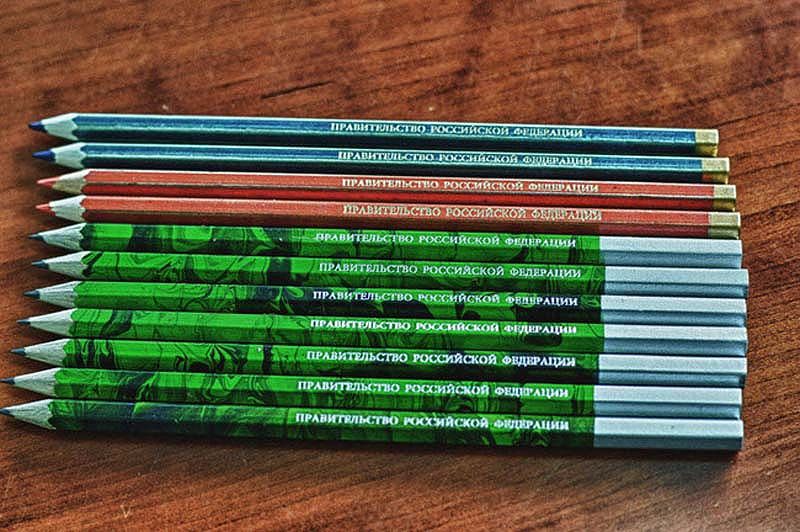

26. When you visit the paintshop I have seen lot of pencils for delivery to the Government of the Russian Federation of a new sample. The tip of the pen symbolizes our national flag. Pencils in special drying technology framework. The regularity of the series looks very unusual and attracts.

27. After painting pencils placed in a batch to be sent to the following sections of the factory.

28. Watch thousands of pencils, colored on the proprietary plant is a great pleasure. This is a very unusual sight.

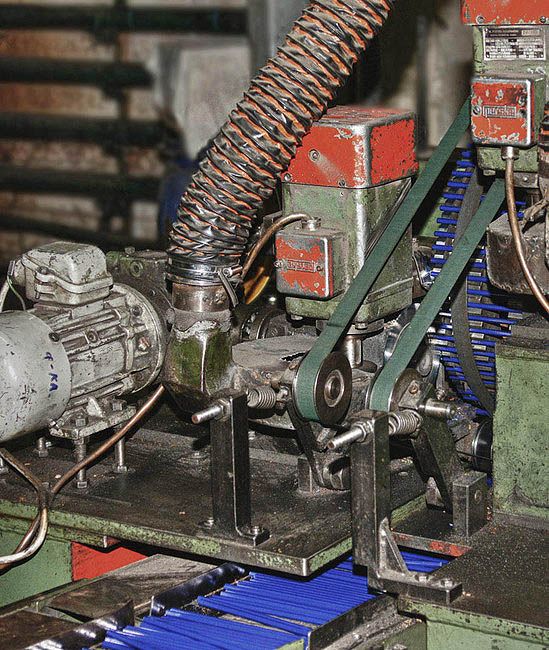

29. Next, a special machine is conducted final mechanical operation - Edges.

30. Technological line of surface finish.

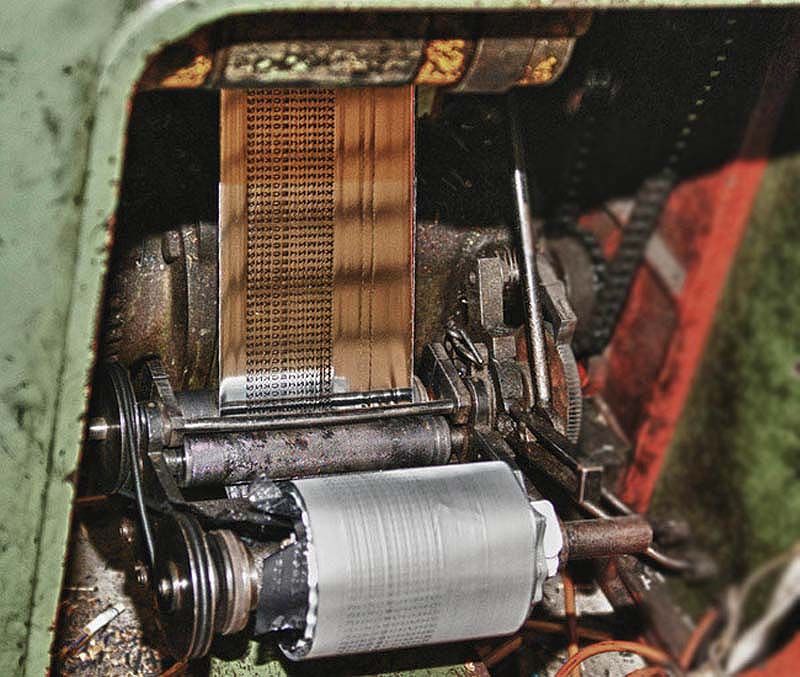

31. Next, a special machine in pencil shall be marked with a special stamp, which is applied to each of the pencil through the tape foil.

32. Storage cabinet dies. Stamps are stored here for the full range of products.

33. If necessary, the packing pencils sharpened on a special machine. The photo displayed intermediate stage sharpening. I was impressed by the speed of the machine. Pencils dropped the pan a continuous stream. Immediately reminded of all personal unsuccessful attempts to sharpen pencils. From these memories, this machine has started to inspire even more respect.

34. The factory produces and there are interesting pencils oval, used in construction and repair.

35. Arrays stockpiled pencils look very unusual and attractive. This anywhere else will not see.

36.

37. On the site packing pencils are sorted and packed by hand. Here a special atmosphere. People work quietly and silently. Many employees have continuous service in a factory for 40 years.

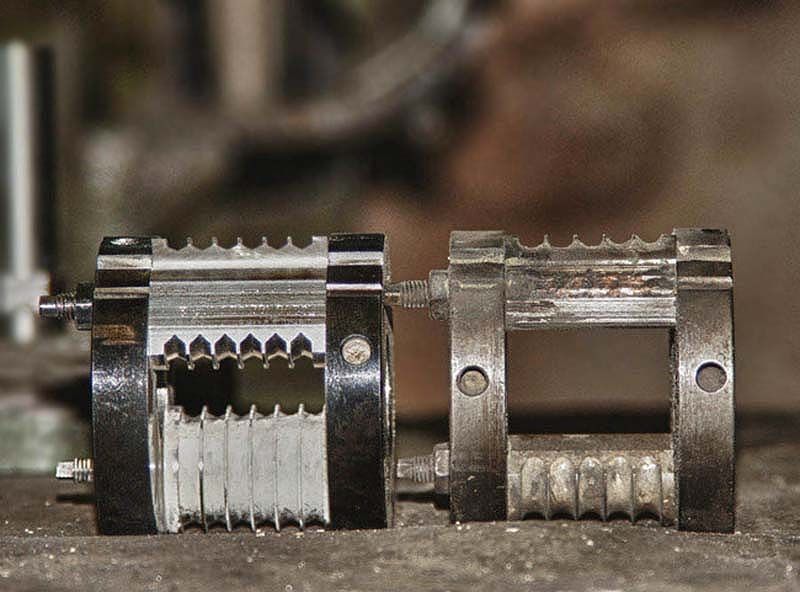

38. The factory has its own equipped laboratory that tested products throughout the production cycle and practiced new production technology. In the picture - Amsler apparatus for determining the resistance to fracture writing rods.

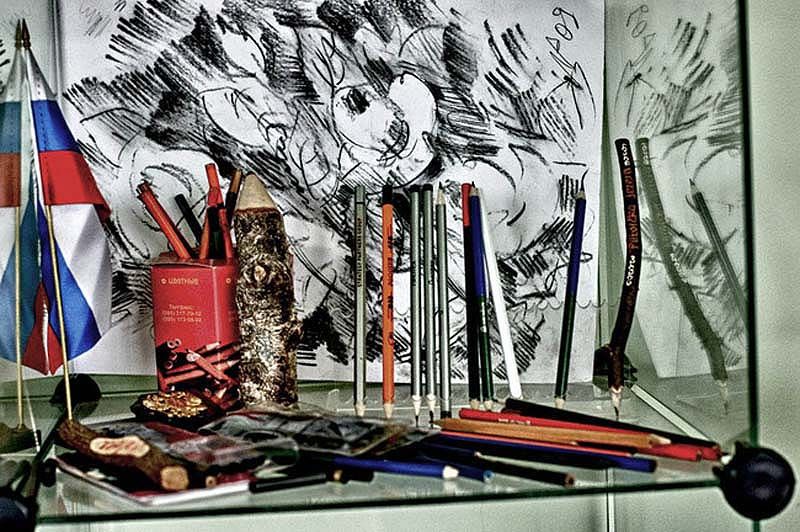

39. Before leaving, I went into the room with display stand factory production. Factory emblem is some nostalgia. After all, these pencils are familiar to all of us since childhood. The factory manufactures several product lines. Professional Series pencils for artists, decorators and designers.

40. Samples pencils supplied to the Russian government. To design a pencil to select the color of the drawing standard desktop devices malachite workers Russian government. But besides that, they have other differences from a pencil, first made their shape with a maximum ergonomically adult hands, and in addition they used a special rod type "lyumograf" for taking notes in the margins and in the diary, he spread out his hand but good eraser erased without damaging the paper.

41. Pencils for engineering drawing:

42. Original souvenirs factory.

43. Visiting the factory was very enjoyable and informative. It was very interesting to see how much of the original technology and work is put into making such a seemingly simple object like a pencil.

44. I want to thank the chief technologist production Marina for help and clarification processes in manufacturing. After visiting the factory, its leaders gave their branded version Ridusa pencils, including delivered to the Government.

" Anda masih mencari jodoh? Lawati http://www.myjodoh.net"

" Kertas Soalan Ramalan Matematik 2010 : http://maths-catch.com/exam"

" Kedai Maya : http://halawahenterprise.blogspot.com/"

" Blog Sahabat RG : http://azwandengkil.blogspot.com"

Terima kasih kerana sudi bersama kami. Untuk mendapatkan maklumat lanjut tentang ReSpeKs Group, sila ke : http://respeks-group.blogspot.com.

Segala email yang tersiar melalui Respeks Group adalah tanggungjawab penulis asal email. Owner atau moderator tidak bertanggungjawab ke atas setiap email yang disiarkan dan sebarang dakwa dakwi tiada kena mengena dengan moderator group.

No comments:

Post a Comment